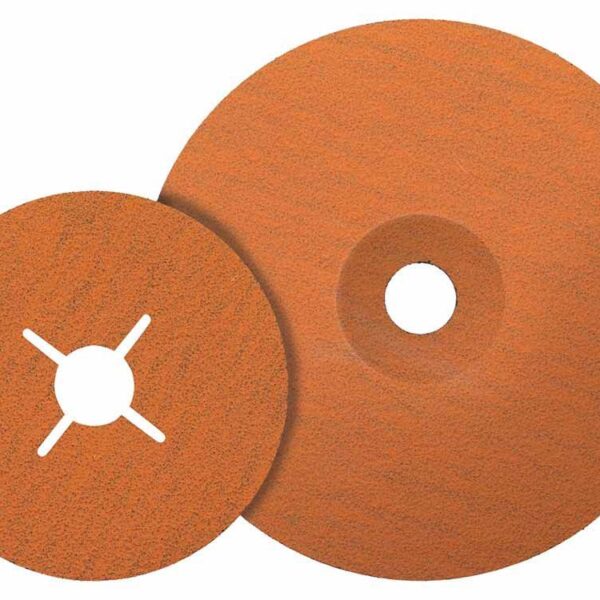

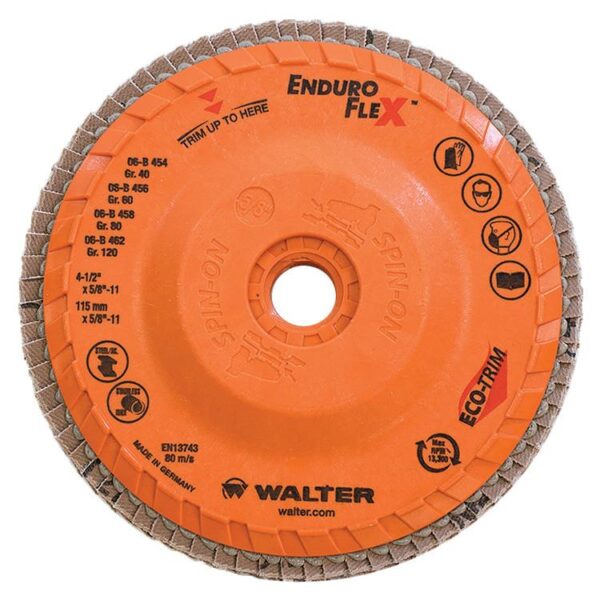

The ENDURO-FLEX one-step finishing discs not only meet but surpass the challenges that the metal fabricating industry faces on a daily basis. With the new ultra sharp and refined zirconium grain, the ENDURO-FLEX finishing disc will stay sharper for a longer period of time while removing more material faster.

In addition, a special top coat continuously cools and lubricates the disc for smooth, vibration-free grinding and sanding from start to finish. Moreover, there is no need to discard the disc when the flap overhang is worn down to the backing because the ENDURO-FLEX disc can be restored to like-new performance by reducing the diameter of the ECO-TRIM backing.

- Arbor: 5/8″-11″

- Max RPM: 13,300

- One step finishing solution to reduce cost

- Quiet, vibration-free grinding

- Raised hub fits all standard grinder back flanges

- With integral thread 5/8″-11″

- ECO-TRIM backing for increased life and flexibility

- Safe and easy to trim

- Always use a back flange

- Backing can be trimmed for working in corners

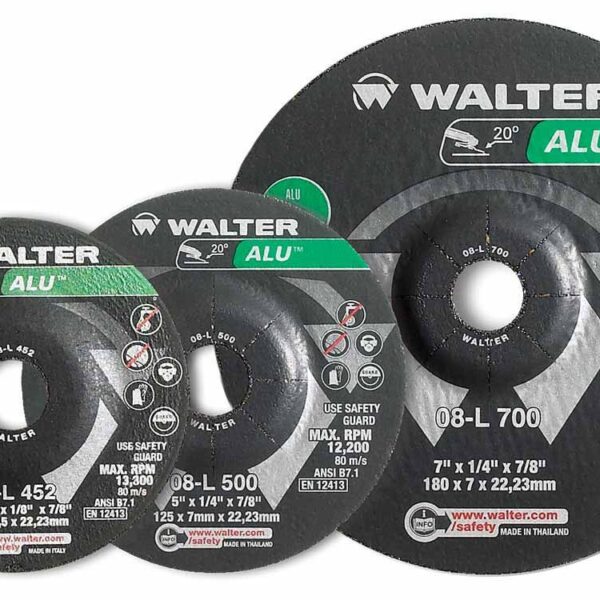

Materials

- Steel

- Stainless steel

Applications

- Grinding and finishing welds

- Surface finishing

SAFETY DATA SHEET

| PRODUCT NUMBER | DIAMETER | ARBOR | GRIT |

| 06B454 | 4.5″ | 5/8″-11″ | 40 |

| 06B456 | 4.5″ | 5/8″-11″ | 60 |

| 06B458 | 4.5″ | 5/8″-11″ | 80 |

| 06B462 | 4.5″ | 5/8″-11″ | 120 |

| 06B504 | 5″ | 5/8″-11″ | 40 |

| 06B506 | 5″ | 5/8″-11″ | 60 |

| 06B508 | 5″ | 5/8″-11″ | 80 |

| 06B512 | 5″ | 5/8″-11″ | 120 |

| 06B604 | 6″ | 5/8″-11″ | 40 |

| 06B606 | 6″ | 5/8″-11″ | 60 |

| 06B608 | 6″ | 5/8″-11″ | 80 |

| 06B612 | 6″ | 5/8″-11″ | 120 |

Environmentally-Friendly

- REDUCED WASTE: ECOTRIM allows trimming the backing pad up to 3 times to expose unused material and extend the life of the product.

- LESS PLASTIC: 35% of the weight of the ECOTRIM is natural fibers to reduce overall quantity of synthetic components required to produce backing pads

- LESS ENERGY CONSUMPTION: The cold cured glue used in conjunction with the ECOTRIM doesn’t require an additional oven curing step and reduces overall energy consumption during the manufacturing process of the discs

Reviews

Clear filtersThere are no reviews yet.